No Dig Pipe Lining Services

24/7 Emergency Response

Residential and Commercial Services

Industry-Leading Technology

1-800-286-FLOW

Modern Pipe Lining Services

"What is No Dig Pipe Lining?”

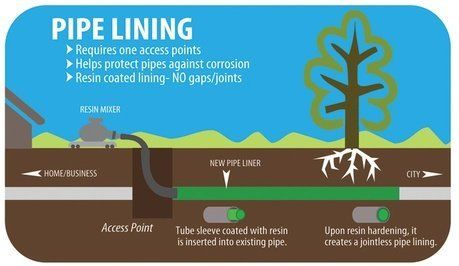

Sometimes referred to as “Trenchless pipe rehabilitation" or “Lateral Lining” this service is able to repair and strengthen underground pipes without needing to dig them up.

The pipe is cleared of all debris, corrosion and tree root intrusions then relined all via a small 2” incision in the ground!”

“How is it done?”

1. First the pipe is cleared of all debris and inspected with our digital HD CCY+TV drain cameras to determine the pipes interior measurements.

2. A liner is placed by our state of the art delivery system and is cured leaving behind a smooth, unbroken, lasting liner that is much more durable than PVC pipe.

3. Finally one last inspection is done with our drain cameras to ensure everything is flowing smoothly!

1. Electric Eel -High pressure water jetting device used to clean debris and roots out of pipes prior to being lined

2. Light Train - Powerful UV light train that cuts curing time by 50%! Typically curing time is 1 hour per 50 feet, but with our specialized equipment Rapid Flow can do it in half the time!

What type of pipe can serviced?

Any pipe between 2” and 24” in diameter and up to 200’ in length.

"What are the advantages of No Dig Pipe Lining?

- Improved water flow due to perfectly smooth surface

- Protection from future corrosion or pinhole leaks, indefinitely

- Prevents further movement

- No joints, leaking displaced and tree root affected joints

- No cracks, breaks, or voids

- No more internal corrosion

- No issues from gaps, perforations, or pinholes

- A protective shield between water contact and the internal area of the pipe

- Increased structural integrity

- No infiltration and exfiltration, ever

- No life disruption from construction

- Repairs and maintenance can be carried out in a fraction of the time

- Completely trenchless system

- It's self-supporting

For more information on our pipe lining services or to schedule your next appointment, please contact Rapid Flow Sewer & Drain Cleaning today.

serving area

Boston, MA

and surrounding areas

Business Hours

24/7 Emergency Service Available

MA Plumbing Corporation #3961-C

Master Plumber #9000-M

Share On: